Implement the Wagner-Whitin algorithm to minimize the total costs of production given a set of constraints

Use python to design an optimal production plan to meet customer demand and minimize the total production costs.

In this Article, we will implement optimal production planning using the Wagner-Whitin method with python.

60+ case studies with source code, dummy data and mathematical concepts here 👉 Analytics Cheat Sheet

Click on the image below to access a full tutorial video to understand the concept behind this solution

You are a production planning manager in a small factory producing radio equipment that serves local and international markets.

Customers send Purchase Orders (PO) to your commercial team with quantities and expected delivery dates.

Your role is to schedule production to deliver on time with a minimum total cost of production that includes

- Setup Costs: fixed costs you have each time you set up a production line

- Production Costs: variable costs per unit produced

- Holding Costs: cost of storage per unit per time

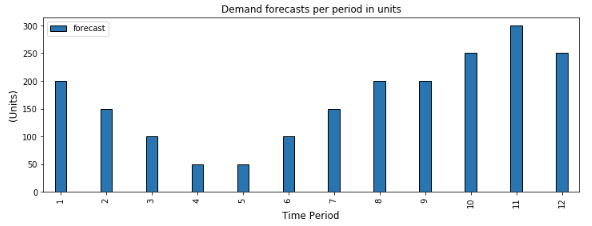

- In our example, the customer ordered products for the next 12 months

This problem can be seen as a generalization of the economic order quantity model that takes into account that demand for the product varies over time.

Wagner and Whitin developed an algorithm for finding the optimal solution by dynamic programming.

The idea is to understand each month if adding the current month's demand quantity to past months' orders can be more economic than setting up a new cycle of production.

This repository code you will find all the code used to explain the concepts presented in the article.

Senior Supply Chain and Data Science consultant with international experience working on Logistics and Transportation operations.

For consulting or advising on analytics and sustainable supply chain transformation, feel free to contact me via Logigreen Consulting

Please have a look at my personal blog: Personal Website