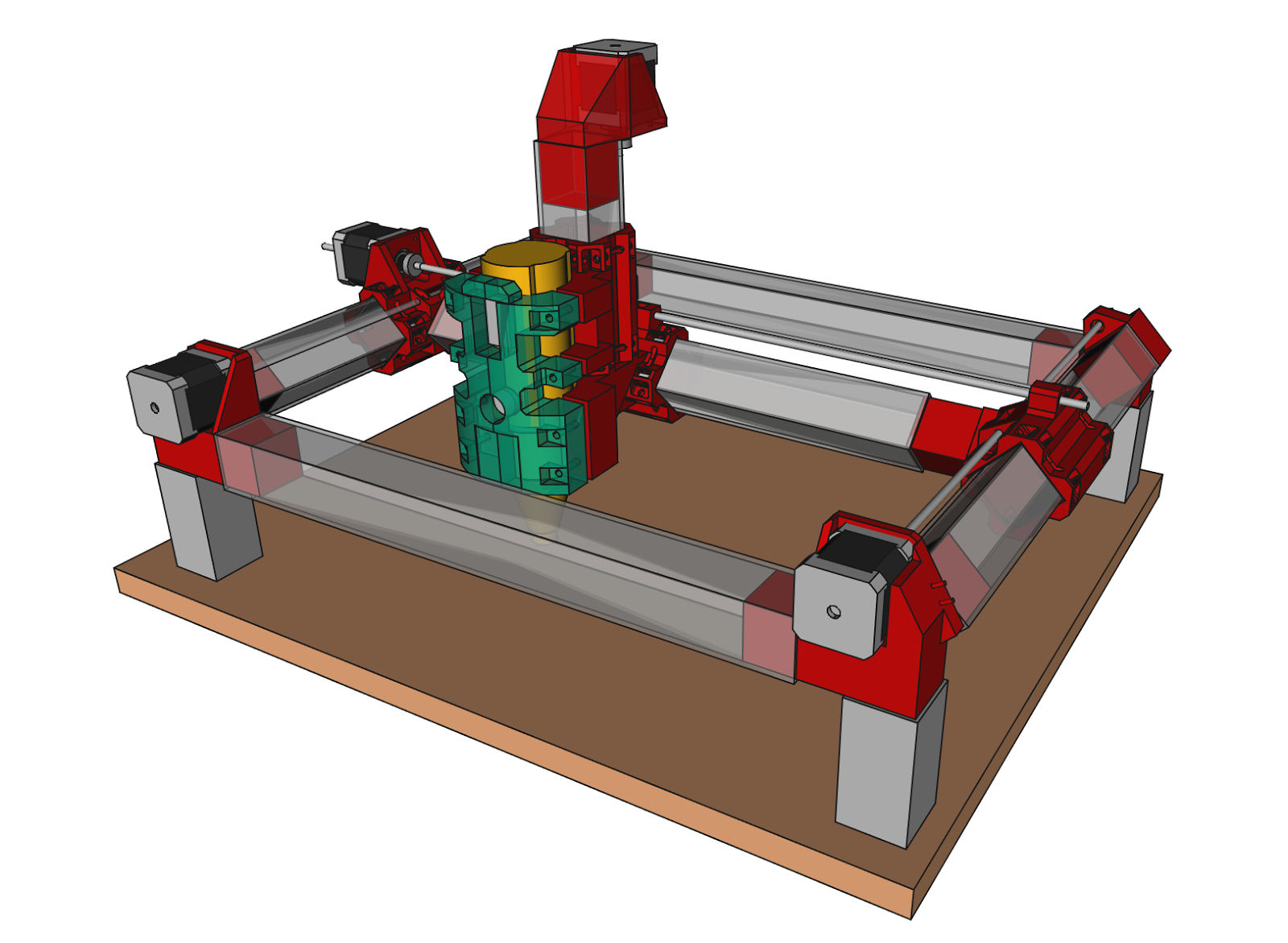

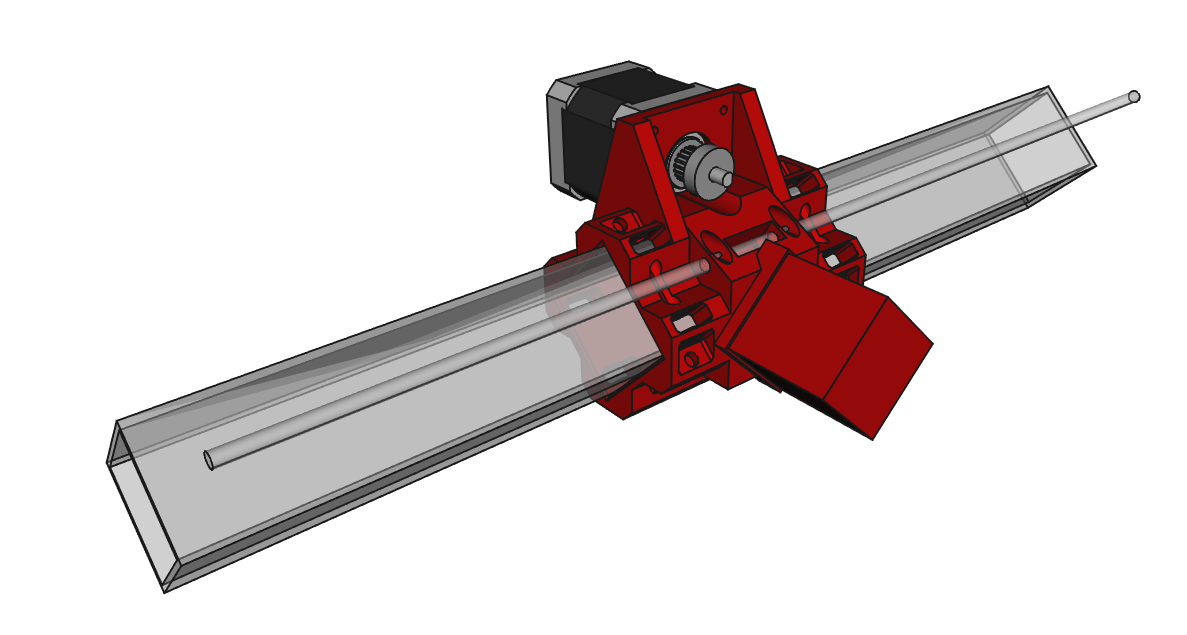

A proof-of-concept, scalable CNC machine that uses 3d printed sliders instead of ball guides or linear bearings. This is a derivation of the design of the NiCr Project

This machine is intended for light loads (soft carving, 3d printing, laser engraving...) and is scalable and cheap to build.

One of the major costs of building a 3d printer with a big work volume (for example 1000x2000x500mm) are the sliders and its frame. Big sized linear bearings require big size calibrated rods, and they end up being very heavy. Linear guides prices are also high and, when they reach some sizes, they require a very stiff mount for being precise.

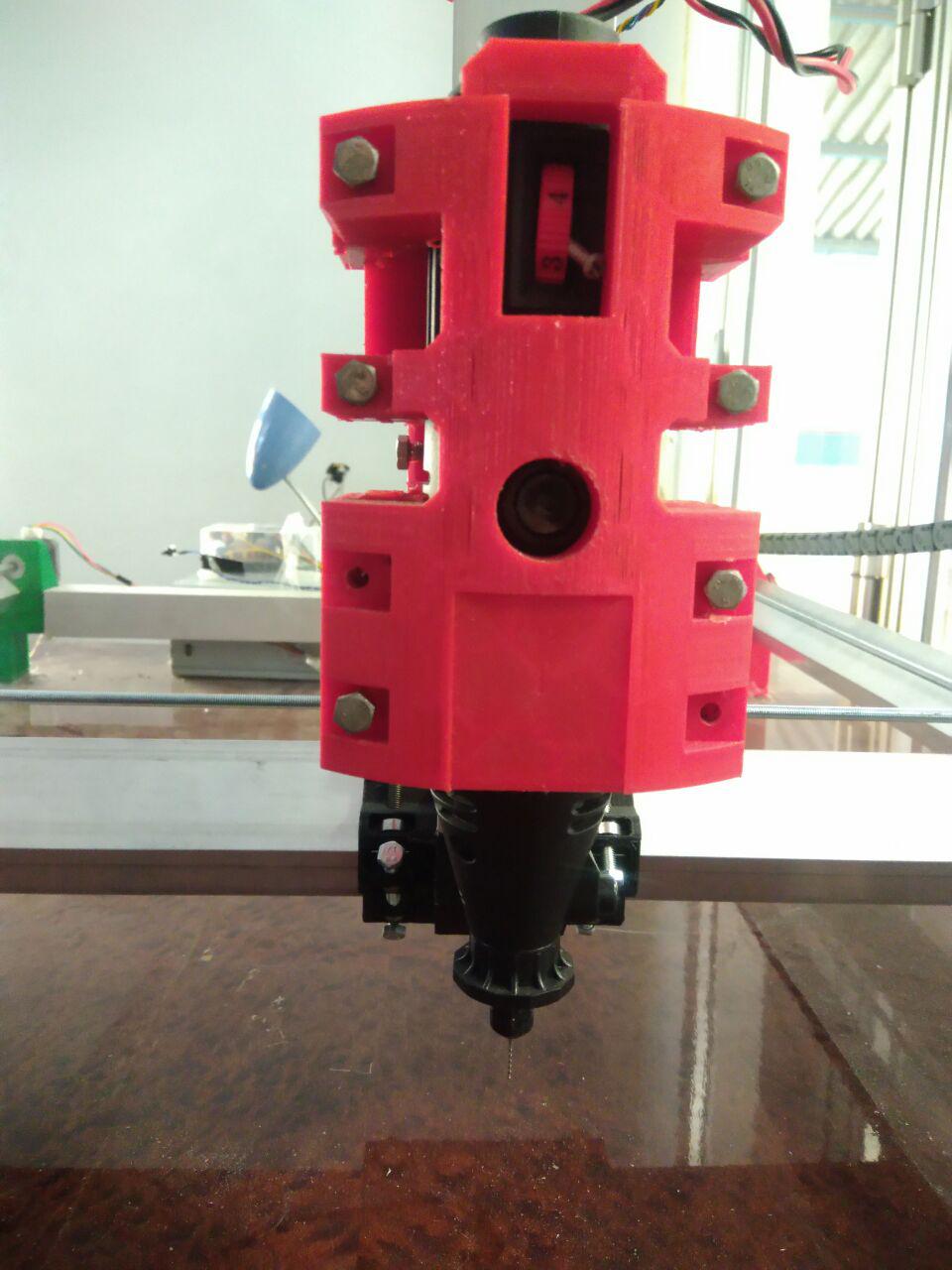

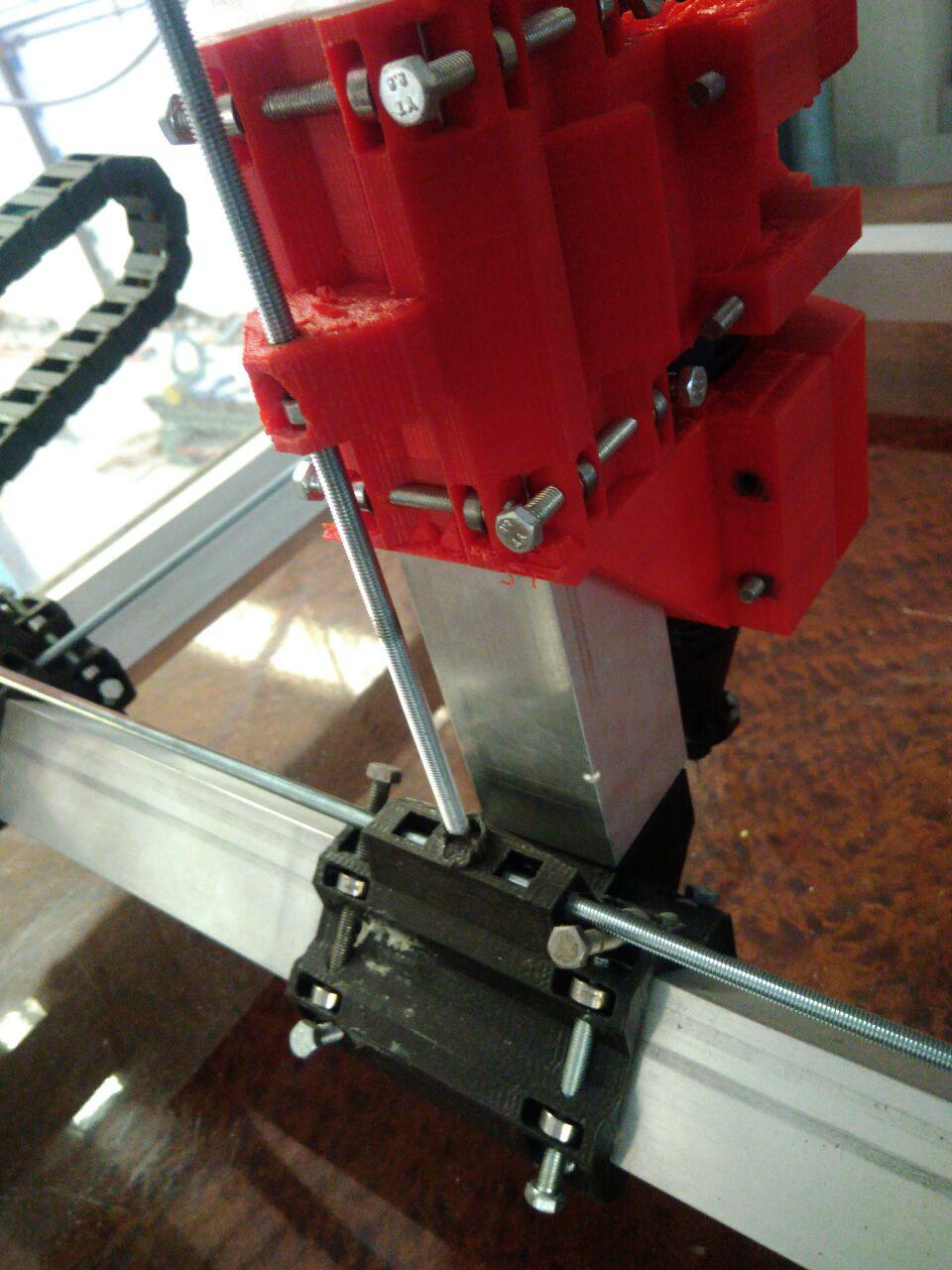

So, what about printing a slider that uses common 10x5x5mm ball bearings and runs over square steel precision profiles?

Something like this:

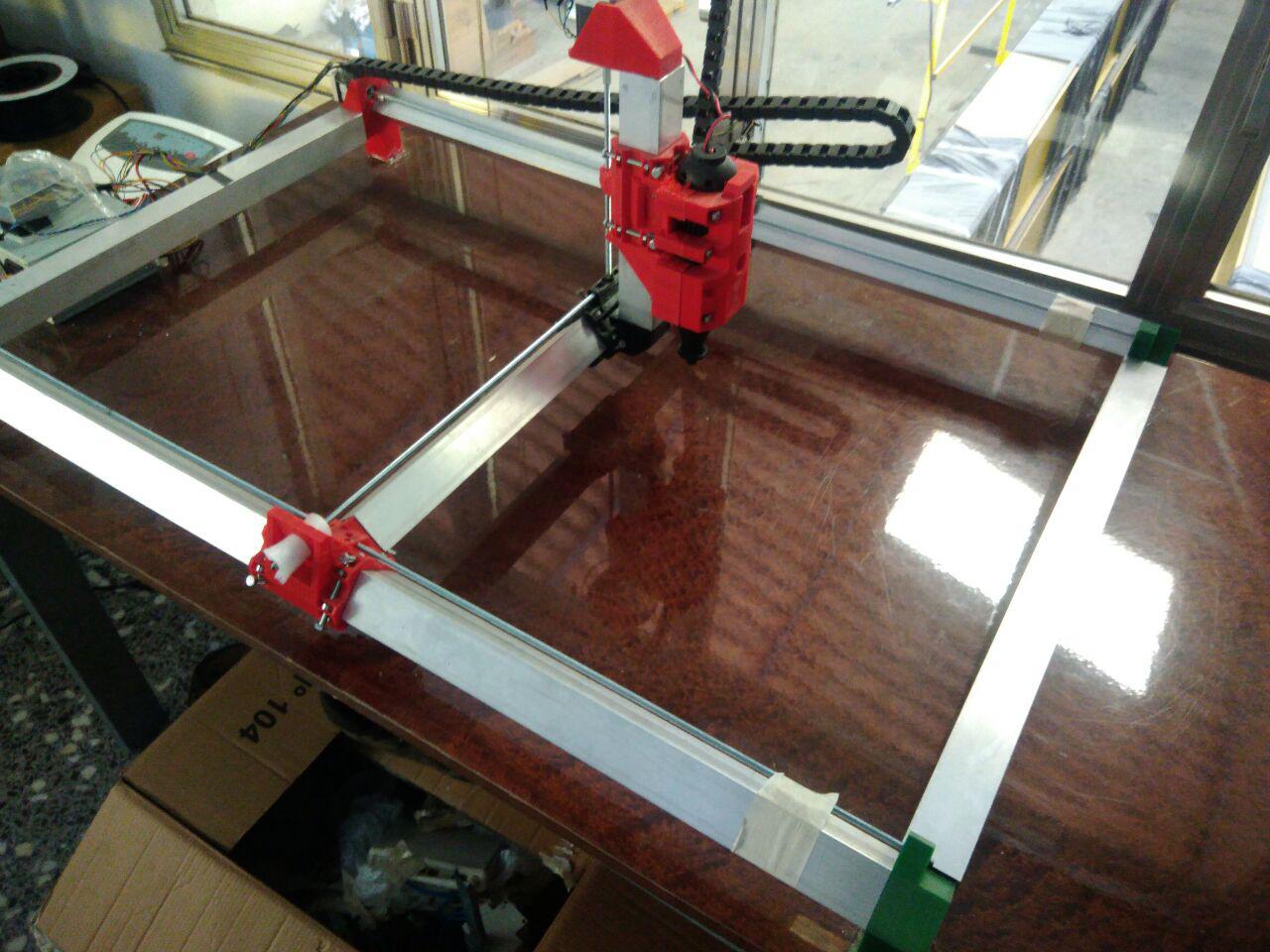

Profiles that are also the frame of the machine and that are also joined together with 3d printed parts. Everything fixed to a desktop table or something stiff enought for the light loads it may generate.

The machine was a rapid prototype I designed on summer of 2016, parts are not parametric and a lot of things can be refined. I have built this machine and currently I use it for carving (logos, pcbs, etc).

TODO:I'll be adding more info as I recover some videos and pictures of this machine in the real life.