As seen in this article in Servo magazine!

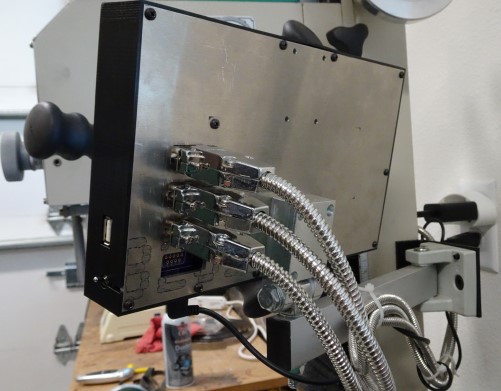

The Smart DRO is a touchscreen digital readout for milling machines. You can see in the photos an installation on a Grizzly mill/drill, replacing the original display head (shown on the mill table). The OEM position sensors for the X, Y, and Z axes directly connect to the back of the unit. Position sensors like these are individually available commercially for mills that do not have them factory installed.

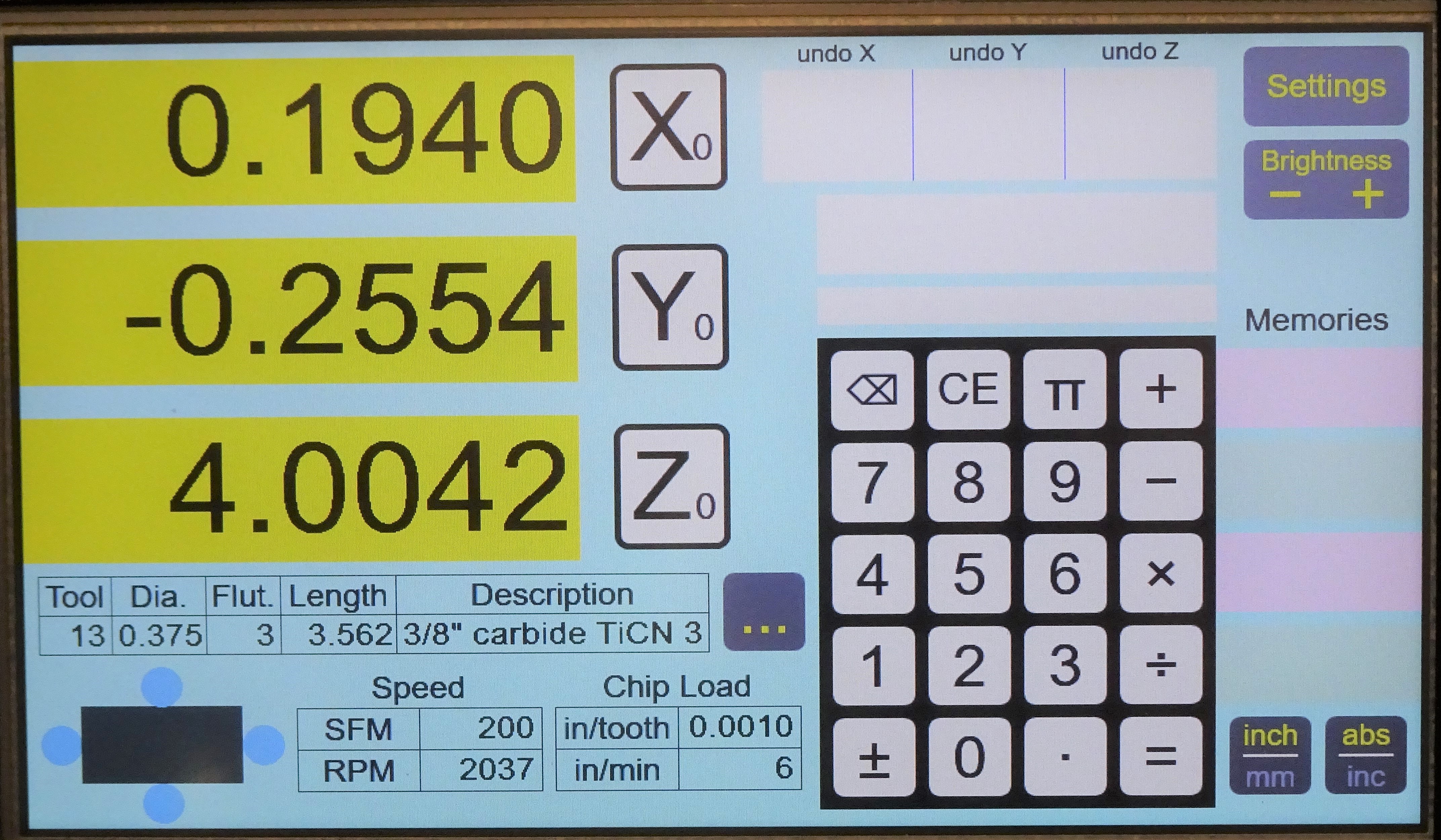

The Smart DRO can greatly simplify milling from dimensioned drawings. If you enter the diameter of the tool it can automatically adjust the display reading by the tool radius. This allows you to cut at the specified dimension without having to add or subtract the radius offset. Note in the lower left corner of the main screen (the dark rectangle with a circle on each side): you can select which side you're cutting so it knows whether to add or subtract the cutter radius.

You can enter the diameter of each tool as you use it, but the Smart DRO can also keep your entire tool library (up to 500 tools) in non-volatile memory. You can enter the list manually or import it from a flash drive if you share it with other programs or devices. The Smart DRO will also calculate feeds and speeds, and it displays the current feed rate when any of the axes move.

Another helpful feature is the undo list for changes in the origin of any axis. If you accidently zero out or set a value to the wrong axis, you can easily recover the origin even if the axis has been moved.

The on-screen calculator allows you to include axis readings in calculations, and copy results back to an axis.

It is industry standard that position sensors use a 9-pin "D" connector (like a PC serial port). However, there is no standard for the pin assignments for the connector! To solve this, the Smart DRO uses a pinout adapter for each axis. A tiny printed circuit board with a single connector routes signals to the correct pins. A set of 3 of these PCBs costs just 45 cents. See the Servo magazine article for more info.

The main component is the 10" LCD touchscreen, specified in the parts list. This repository includes all other aspects of the hardware design needed to build this project as shown. These elements include:

- Custom electronics design, with printed circuit board ready for fabrication.

- Enclosure design, using a 3D-printed bezel and machined aluminum back.

A separate repository has the microcontroller firmware and graphics images.

Here are the critical links:

- The Servo magazine article has complete instructions on how to build it.

- The Touchscreen-DRO-Firmware repository has firmware and everything else you need, bundled into a release.

- Touchscreen at BuyDisplay.com. Be sure to select options per the parts list.

- Main PCB shared at OSH Park. The EAGLE CAD for the PCB is included is you want to use another PCB source.

- Pinout PCBs at OSH Park. Pinouts are specified by a 4-digit number where the digits are the pin numbers on the 9-pin D-connector for GND, +5V, A, & B, respectively.

- Tool Library Manager for making tool libary files the Smart DRO can import.